Unlocking the World of Metric Steel Sizes: A Comprehensive Guide

Imagine a world where building anything, from skyscrapers to bicycles, depended on a universal language of measurement. In the realm of steel construction and manufacturing, this universal language is the metric system, and understanding metric steel sizes is the key to unlocking its potential. This comprehensive guide explores the intricate world of metric steel dimensions, offering insights into its history, importance, and practical applications.

Navigating the world of steel can seem daunting, especially with the variety of shapes, grades, and, importantly, sizes available. When dealing with metric steel sizes, we’re talking about millimeters and centimeters, not inches and feet. This shift to the metric system offers a standardized and globally recognized approach to specifying steel dimensions, simplifying international trade and collaboration.

The metric system for steel sizes emerged from the need for a more consistent and logical system of measurement. Before its widespread adoption, variations in regional units created confusion and inefficiencies. The metric system, with its base-ten structure, simplified calculations and facilitated communication across borders. This transition has revolutionized the steel industry, enabling seamless exchange of information and materials worldwide.

The importance of understanding metric steel sizes cannot be overstated. Whether you’re an architect designing a bridge, an engineer calculating load-bearing capacities, or a fabricator cutting and welding steel components, accurate dimensional information is paramount. Using incorrect measurements can lead to costly errors, structural instability, and project delays. Mastering metric steel dimensions is essential for ensuring precision and efficiency in every stage of a project.

One of the main issues related to metric steel sizes is the potential for confusion when converting from imperial units. While conversion charts and online calculators are readily available, errors can still occur, particularly when dealing with complex shapes or tolerances. It’s crucial to double-check conversions and ensure everyone involved in a project is working with the same units of measurement.

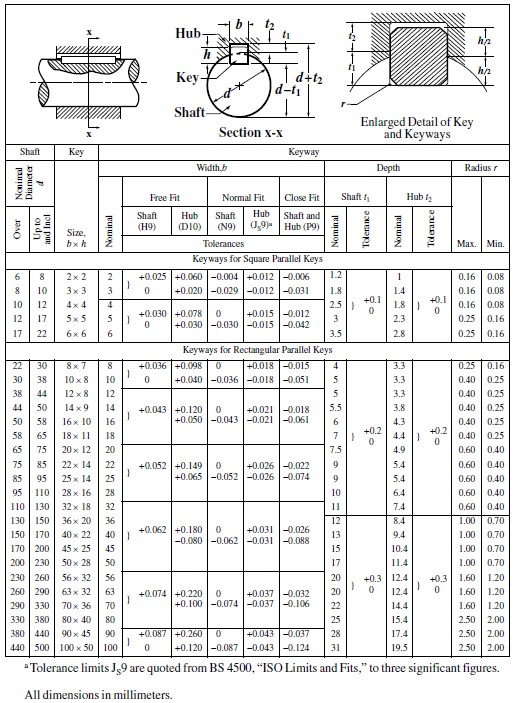

Standard metric steel sizes are typically expressed in millimeters (mm). For instance, a common structural steel section might be designated as a 100 x 50 x 6 mm angle, indicating its legs are 100 mm and 50 mm long, with a thickness of 6 mm. Understanding these designations is fundamental to selecting the appropriate steel for any given application.

One benefit of using metric steel sizes is the increased precision it offers compared to imperial units. The smaller increments of millimeters allow for finer adjustments and tighter tolerances, leading to more accurate fabrication and assembly. This precision translates to improved structural integrity and overall quality of the finished product.

Another advantage is the global standardization provided by the metric system. Since the majority of the world uses metric units, adopting metric steel sizes simplifies international trade and collaboration. This standardization eliminates the need for complex conversions and reduces the risk of errors associated with differing measurement systems.

A third benefit is the ease of calculation inherent in the metric system's base-ten structure. Converting between different metric units, such as millimeters to centimeters or meters, is a straightforward process, minimizing the potential for mathematical errors and simplifying design and engineering calculations.

When working with metric steel sizes, always double-check your measurements and conversions. Use reliable resources, such as standardized tables and online calculators, to ensure accuracy. Clear communication between all stakeholders is also essential to prevent misunderstandings and errors related to units of measurement.

Advantages and Disadvantages of Metric Steel Sizes

| Advantages | Disadvantages |

|---|---|

| Global standardization | Potential for confusion during conversion from imperial units |

| Increased precision | Familiarity with imperial units in some regions |

| Ease of calculation |

Best practices for working with metric steel sizes include consistent use of millimeters throughout the project, double-checking conversions, using standardized size charts, and maintaining clear communication about units of measurement with all stakeholders. These practices minimize errors and promote efficiency in all phases of a project, from design to fabrication.

Frequently Asked Questions:

1. What is the most common unit for metric steel sizes? Millimeters (mm)

2. How do I convert inches to millimeters? Multiply the inch value by 25.4.

3. Where can I find standardized metric steel size charts? Various online resources and industry publications provide these charts.

In conclusion, understanding and utilizing metric steel sizes is paramount in the modern construction and manufacturing landscape. From simplifying global collaboration to ensuring structural integrity, the benefits of adopting this standardized system are numerous. By embracing the precision and efficiency offered by metric dimensions, we unlock a world of possibilities in steel construction and pave the way for a more interconnected and standardized future. Start incorporating these principles into your projects today to experience the full potential of metric steel sizes.

Decoding the love is patient love is kind meme phenomenon

The undeniable allure of the black gel ink rollerball pen

How to see save tiktok profile pictures a quick guide