Unlocking the Secrets of Metric Bolt Torque Specs

Ever wondered about the magic behind properly tightened bolts? It's not just about brute force, it's about precision. And that's where the world of metric bolt torque specifications, often laid out in handy charts, comes into play. We're talking about the specific amount of rotational force, measured in Newton-meters (Nm), needed to achieve a secure and reliable connection. Getting this right is crucial for everything from assembling furniture to building skyscrapers.

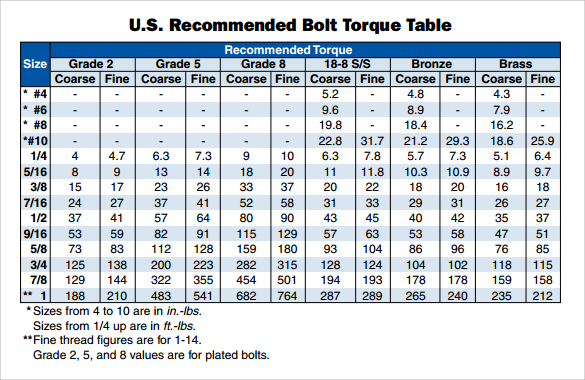

Imagine a world without standardized torque values. Chaos, right? Stripped threads, loose bolts, and potentially catastrophic failures would be commonplace. Thankfully, we have metric bolt torque charts to guide us. These charts provide recommended torque values for various bolt sizes, grades, and materials. They are the unsung heroes of countless engineering projects, ensuring everything stays firmly in place.

The history of standardized torque values is intertwined with the rise of industrialization and mass production. As manufacturing processes became more complex, the need for consistent and reliable fastening methods became paramount. This led to the development of standardized bolt sizes and grades, along with corresponding torque specifications. Metric bolt torque charts evolved as a practical tool to organize and disseminate this crucial information.

The importance of consulting a proper metric bolt torque specification chart cannot be overstated. Over-torquing a bolt can lead to stripped threads or even bolt failure. Under-torquing, on the other hand, can result in a loose connection, which can vibrate loose and lead to dangerous situations. These charts provide the sweet spot, the optimal torque value that ensures a secure and reliable connection.

One common issue encountered is the sheer variety of factors affecting the correct torque value. Material type, bolt grade, lubricant use, and even temperature can influence the ideal torque. That's why it's crucial to consult a comprehensive torque chart specific to your application. Fortunately, numerous resources, both online and offline, provide detailed metric bolt tightening guides.

A metric bolt torque chart typically lists bolt sizes (diameter and thread pitch) alongside corresponding torque values in Newton-meters (Nm). Some charts also factor in bolt grade (e.g., 8.8, 10.9) and lubricant conditions (dry or lubricated). For example, an M6x1.0 bolt of grade 8.8 might require a torque of 10 Nm when dry and 7 Nm when lubricated.

Using the correct torque prevents damage to bolts and fastened materials, ensuring the integrity of assembled components. It also contributes to consistent clamping force, crucial for achieving uniform pressure distribution and preventing leaks or loosening over time.

Accurate torque application enhances safety by preventing joint failures that could lead to accidents. In critical applications like automotive or aerospace engineering, adhering to specific torque specifications is paramount for ensuring structural integrity and preventing catastrophic failures.

Consulting a torque chart streamlines assembly processes by providing clear guidance on fastener tightening. This minimizes guesswork and reduces the likelihood of errors, leading to faster and more efficient assembly operations.

To use a metric bolt torque chart effectively, first identify the bolt size and grade. Then, consider the lubrication condition (dry or lubricated) and locate the corresponding torque value in the chart. Finally, use a calibrated torque wrench to apply the specified torque to the bolt.

Advantages and Disadvantages of Using Torque Charts

| Advantages | Disadvantages |

|---|---|

| Standardized Torque Values | Potential for Inaccurate Information if using the wrong chart |

| Reduced Risk of Over/Under Torquing | Charts May Not Cover All Possible Scenarios |

| Improved Safety and Reliability | Requires Understanding of Bolt Grades and Lubrication Conditions |

Best Practices for Implementing Metric Bolt Torque Charts:

1. Use a Calibrated Torque Wrench: Ensure your torque wrench is properly calibrated to ensure accurate torque application.

2. Clean Threads: Clean bolt threads and the mating surface to remove debris that could affect torque readings.

3. Proper Lubrication: Use the correct lubricant as specified in the torque chart. Different lubricants can significantly affect the required torque.

4. Tighten in Stages: For larger bolts, tighten in stages following a specific sequence to ensure even clamping force.

5. Consult Manufacturer Specifications: Always refer to the manufacturer's specifications for specific torque recommendations for your application.

FAQs:

1. What is torque? Torque is a rotational force measured in Newton-meters (Nm).

2. Why are torque charts important? They provide standardized torque values for different bolt sizes and grades.

3. What happens if I over-torque a bolt? Over-torquing can damage threads or cause bolt failure.

4. What happens if I under-torque a bolt? Under-torquing can result in a loose connection.

5. Where can I find metric bolt torque charts? Numerous online and offline resources provide torque charts.

6. What is bolt grade? Bolt grade indicates the strength of the bolt.

7. Why is lubrication important? Lubrication reduces friction and affects the required torque.

8. How do I use a torque wrench? Refer to the torque wrench's instructions for proper usage.

Tips and Tricks: Keep your torque wrenches calibrated regularly. Clean threads before tightening. Use the correct lubricant.

In conclusion, understanding and applying the principles of metric bolt torque specifications is fundamental to safe and reliable assembly. Utilizing accurate torque charts, combined with the proper tools and techniques, ensures optimal clamping force, prevents damage, and contributes to the longevity and safety of any structure or machine. Metric bolt torque charts aren't just tables of numbers; they are the guardians of structural integrity, holding our world together, one precisely tightened bolt at a time. Don't underestimate the power of a properly torqued bolt – it's the silent force that keeps our world running smoothly. Take the time to consult a chart, use the right tools, and torque it right!

Unveiling the ford 68l oil capacity a comprehensive guide

Unlocking liga mx on pc ea fc 24 mods

Short topics for catholic marriage enrichment