Transform Your Floors: The Ultimate Guide to Behr Epoxy Floor Coatings

Ready to revolutionize your garage, basement, or workshop floor? Tired of dull, stained concrete that chips and cracks? A Behr epoxy floor coating might be just what you need to create a durable, beautiful, and easy-to-maintain surface.

Behr epoxy floor coatings offer a high-performance solution for concrete surfaces, providing a protective shield against wear, tear, and stains. This guide dives deep into the world of Behr epoxy floor coatings, from understanding their origins and benefits to addressing common application challenges and providing expert tips for achieving professional-looking results.

While specific information regarding the historical origins of Behr epoxy floor coating formulations is not readily available, epoxy coatings in general have been a staple in industrial settings for decades. Their resilience, chemical resistance, and ability to withstand heavy traffic made them ideal for factory floors and warehouses. Over time, epoxy coatings have become increasingly popular for residential use, offering homeowners a robust and attractive flooring option for garages, basements, and other high-traffic areas. Behr, known for its quality paints and primers, has entered this market, offering DIY-friendly epoxy floor coating systems designed for homeowners.

The significance of a Behr epoxy floor coating lies in its ability to transform a plain concrete surface into a durable and aesthetically pleasing space. These coatings offer superior protection against abrasion, impact, chemicals, and stains, making them an excellent choice for areas prone to spills, heavy equipment, or frequent foot traffic. Beyond their protective qualities, Behr epoxy floor coatings are also available in a range of colors and finishes, allowing homeowners to customize their space and enhance its visual appeal.

One of the key issues surrounding Behr epoxy floor coating, and epoxy coatings in general, is proper surface preparation. The success of the application hinges on a clean, dry, and properly profiled concrete surface. Moisture, grease, or existing coatings can interfere with adhesion, leading to premature failure. Therefore, meticulous preparation is crucial for achieving long-lasting results.

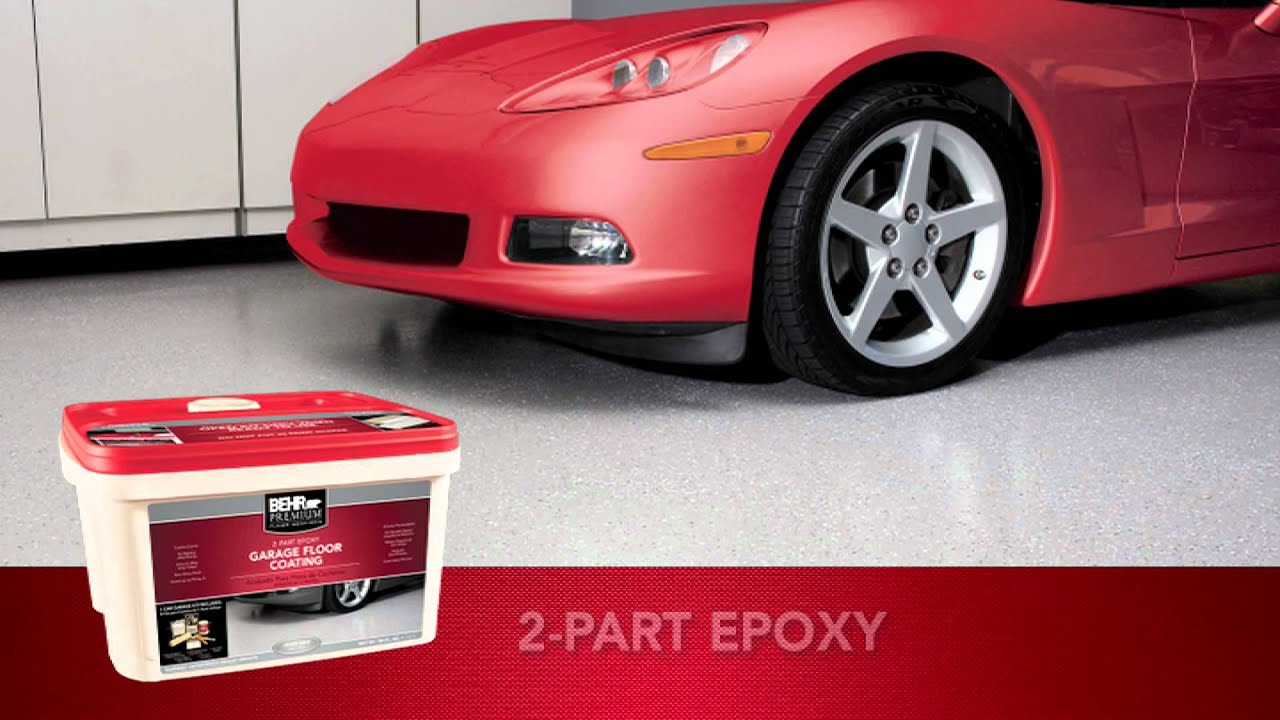

A Behr epoxy floor coating system typically consists of two main components: the resin and the hardener. When these two components are mixed, a chemical reaction occurs, creating a durable and resistant coating. Simple examples of this two-part system are seen in most Behr epoxy garage floor kits.

Benefits of Behr Epoxy Floor Coating:

1. Durability: Behr epoxy floor coatings provide exceptional resistance to abrasion, impact, and chemicals, protecting your concrete from daily wear and tear. For example, dropping heavy tools on an epoxy-coated floor is less likely to cause damage compared to bare concrete.

2. Easy Maintenance: The smooth, non-porous surface of an epoxy coating is easy to clean and resists stains. Spilled oil, grease, or other liquids can be simply wiped away, keeping your floor looking pristine.

3. Enhanced Aesthetics: Behr epoxy floor coatings are available in a variety of colors and finishes, allowing you to transform a dull concrete floor into a visually appealing space.

Application Steps:

1. Surface Preparation: Thoroughly clean and etch the concrete surface to ensure proper adhesion.

2. Mixing: Carefully mix the resin and hardener according to the manufacturer's instructions.

3. Application: Apply the mixed epoxy using a roller or brush, working in manageable sections.

4. Drying Time: Allow sufficient drying time between coats and before using the floor.

Advantages and Disadvantages of Behr Epoxy Floor Coating

| Advantages | Disadvantages |

|---|---|

| Durability | Surface Preparation Intensive |

| Easy to Clean | Sensitivity to Moisture |

| Variety of Colors and Finishes | Limited Lifespan Compared to Other Industrial Coatings |

FAQ:

1. How long does Behr epoxy floor coating last? - Several years with proper maintenance.

2. Can I apply Behr epoxy over existing paint? - Generally no, the surface needs to be bare concrete.

3. How do I clean a Behr epoxy floor? - Mild soap and water are usually sufficient.

4. What is the best temperature for application? - Refer to manufacturer's instructions for specific temperature range.

5. How long does it take to cure? - Usually several days for full cure.

6. What safety precautions should I take? - Wear proper ventilation and protective gear.

7. Can I use Behr epoxy outdoors? - Some formulations are suitable for outdoor use, check the product label.

8. How much does Behr epoxy floor coating cost? - Cost varies depending on the product and coverage area.

Conclusion: Behr epoxy floor coating offers a powerful solution for transforming dull, vulnerable concrete floors into durable, beautiful, and easy-to-maintain surfaces. While proper surface preparation is essential, the long-term benefits of increased resilience, simplified cleaning, and enhanced aesthetics make Behr epoxy floor coatings a worthwhile investment. From garages and workshops to basements and patios, the versatility and protective qualities of this coating can elevate any space. Consider Behr epoxy floor coating for your next flooring project and experience the transformative difference it can make. Research the various Behr epoxy products available, carefully follow the manufacturer's instructions, and enjoy a beautiful, long-lasting floor for years to come. Take action today and discover the potential of your concrete surfaces!

Decoding the acdelco pf63e oil filter cross reference guide more

What exactly do doctors do unpacking the medical profession

Finding your dream vintage rav4 a guide to first generation rav4s in michigan