The Whimsical Physics of Rubber Band Cars: A Journey into Kinetic Energy

What propels a toy car across the floor without batteries or an engine? The answer lies in the elegant simplicity of stored energy, a concept beautifully illustrated by the rubber band powered car. This seemingly humble project opens a doorway to understanding fundamental principles of physics, engineering, and design, offering a hands-on learning experience that transcends age and expertise.

The allure of a rubber band car lies in its accessibility. With just a few readily available materials – a chassis, axles, wheels, and of course, the eponymous rubber band – one can construct a vehicle powered by the potential energy coiled within that stretched elastic loop. As the rubber band unwinds, this stored potential energy transforms into kinetic energy, the energy of motion, propelling the car forward. This transformation, this dance between potential and kinetic energy, is the heart of the rubber band car science project.

The origins of the rubber band car are somewhat shrouded in the mists of time, likely coinciding with the popularization of rubber bands themselves in the mid-19th century. These elastic wonders quickly found their way into toys and gadgets, with the rubber band powered car emerging as a natural application of their energy-storing properties. While the precise inventor remains unknown, the concept's enduring popularity speaks to its inherent educational value and the sheer joy of watching a self-made creation come to life.

The importance of rubber band car projects in education cannot be overstated. They provide a tangible, interactive way to explore scientific concepts like potential and kinetic energy, friction, and Newton's Laws of Motion. Moreover, building a rubber band car encourages problem-solving skills, fosters creativity in design, and promotes a deeper understanding of the engineering design process.

A common challenge in rubber band car construction is optimizing the energy transfer from the rubber band to the wheels. Friction, air resistance, and the car's weight all play a role in determining how far and fast it will travel. Addressing these factors requires careful consideration of materials, design, and the winding mechanism. For example, lightweight materials like balsa wood or cardboard minimize the car's mass, allowing for greater acceleration. Similarly, minimizing friction in the axles and wheels can significantly improve performance.

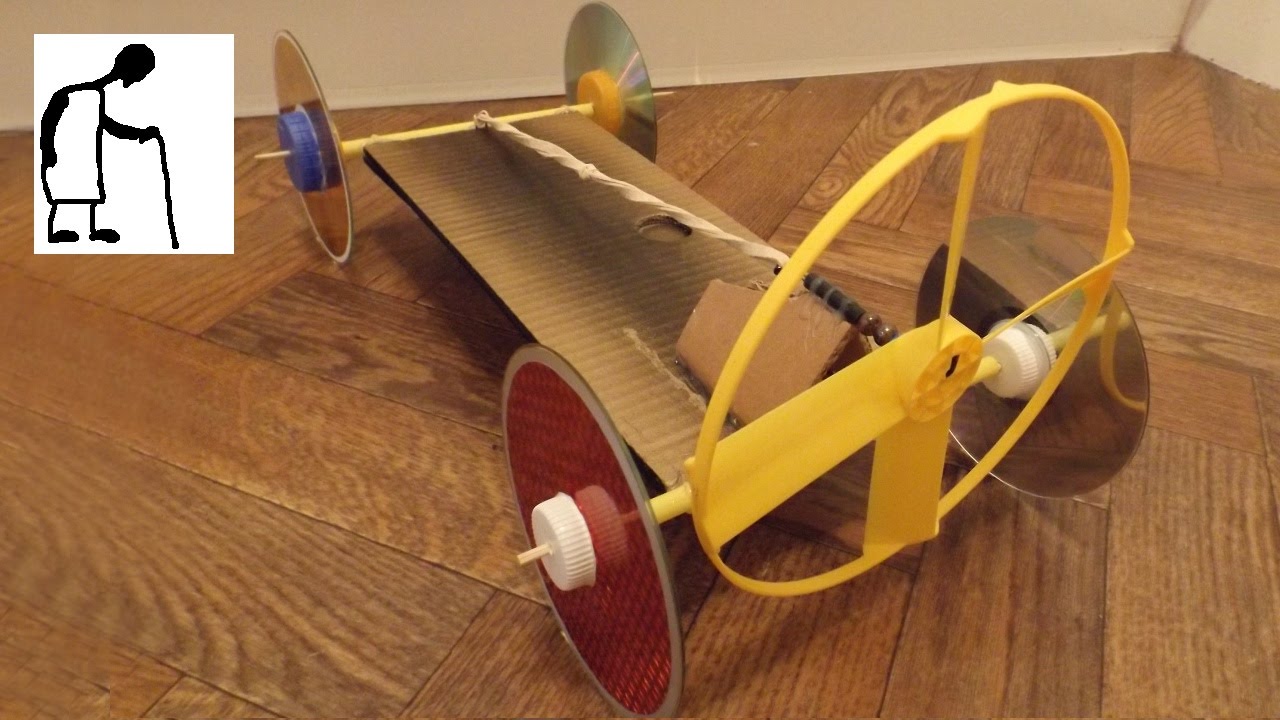

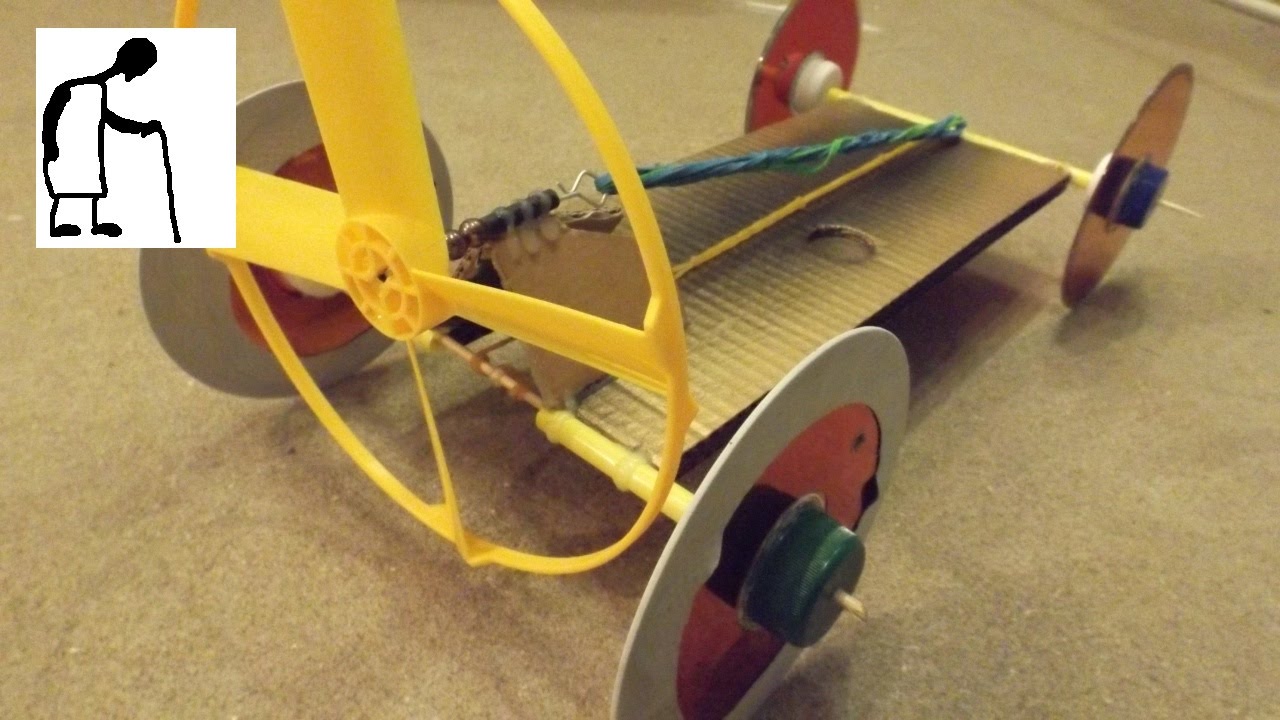

A simple rubber band car can be built using a cardboard box for the chassis, wooden dowels for axles, bottle caps or CDs for wheels, and a strong rubber band for propulsion. The rubber band is attached to the rear axle, and winding it up stores potential energy. Upon release, the unwinding rubber band turns the axle, propelling the car forward. Experimenting with different rubber band sizes, wheel diameters, and chassis designs allows for exploration of how these variables affect performance.

Advantages and Disadvantages of Rubber Band Car Projects

| Advantages | Disadvantages |

|---|---|

| Cost-effective and uses readily available materials | Limited range and speed compared to other powered vehicles |

| Excellent educational tool for understanding basic physics and engineering principles | Can be fragile depending on the materials used |

| Encourages creativity and problem-solving skills | Performance can be affected by environmental factors like temperature and humidity |

Best Practices:

1. Choose lightweight materials for the chassis and wheels.

2. Minimize friction in the axles by using lubricants or smooth materials.

3. Experiment with different rubber band sizes and lengths to find the optimal power source.

4. Ensure the wheels are securely attached to the axles to prevent slippage.

5. Test and refine your design iteratively to improve performance.

FAQs:

1. What makes a rubber band car move? Stored potential energy in the stretched rubber band converts to kinetic energy.

2. How can I make my rubber band car go faster? Reduce friction, use a larger rubber band, or increase wheel diameter.

3. What materials can I use to build a rubber band car? Cardboard, wood, plastic, bottle caps, and CDs are common choices.

4. What is the science behind a rubber band car? It demonstrates the principles of potential and kinetic energy, friction, and Newton's laws of motion.

5. How can I improve the performance of my rubber band car? Minimize friction, optimize weight, and experiment with different designs.

6. What are some common problems with rubber band cars? Axle slippage, excessive friction, and weak chassis construction.

7. Where can I find instructions for building a rubber band car? Numerous online resources and books provide detailed instructions.

8. Are there competitions for rubber band cars? Yes, many schools and science fairs host rubber band car races.

The rubber band car, in its unassuming simplicity, offers a powerful lesson in the fundamentals of physics and engineering. It provides a tangible connection to abstract concepts, fostering a deeper understanding of the world around us. From the potential energy coiled within the stretched rubber band to the kinetic energy that propels the car forward, this project embodies the beauty of scientific principles in action. Embrace the challenge, explore the possibilities, and discover the joy of building your own rubber band powered car – a testament to the power of human ingenuity and the enduring fascination with simple machines.

Deciphering your fuel gauge understanding the sending unit and its secrets

Unlocking the secrets of the ac 41 985 spark plug

The allure of kim soo hyun in high definition