Taming Unruly Systems: The Power of PI Control

Imagine a world without consistent temperatures in your home, erratic speed control in your car, or unpredictable industrial processes. Sounds chaotic, right? That's where the unsung hero of control systems, the PI controller, steps in. These ingenious devices are the backbone of countless applications, tirelessly working to maintain stability and precision.

PI controllers, short for Proportional-Integral controllers, are a fundamental component in the field of control systems engineering. They act as the brains behind automated systems, constantly monitoring and adjusting outputs to achieve a desired target value, often referred to as the setpoint. Think of a thermostat regulating your home's temperature – a perfect example of PI control in action.

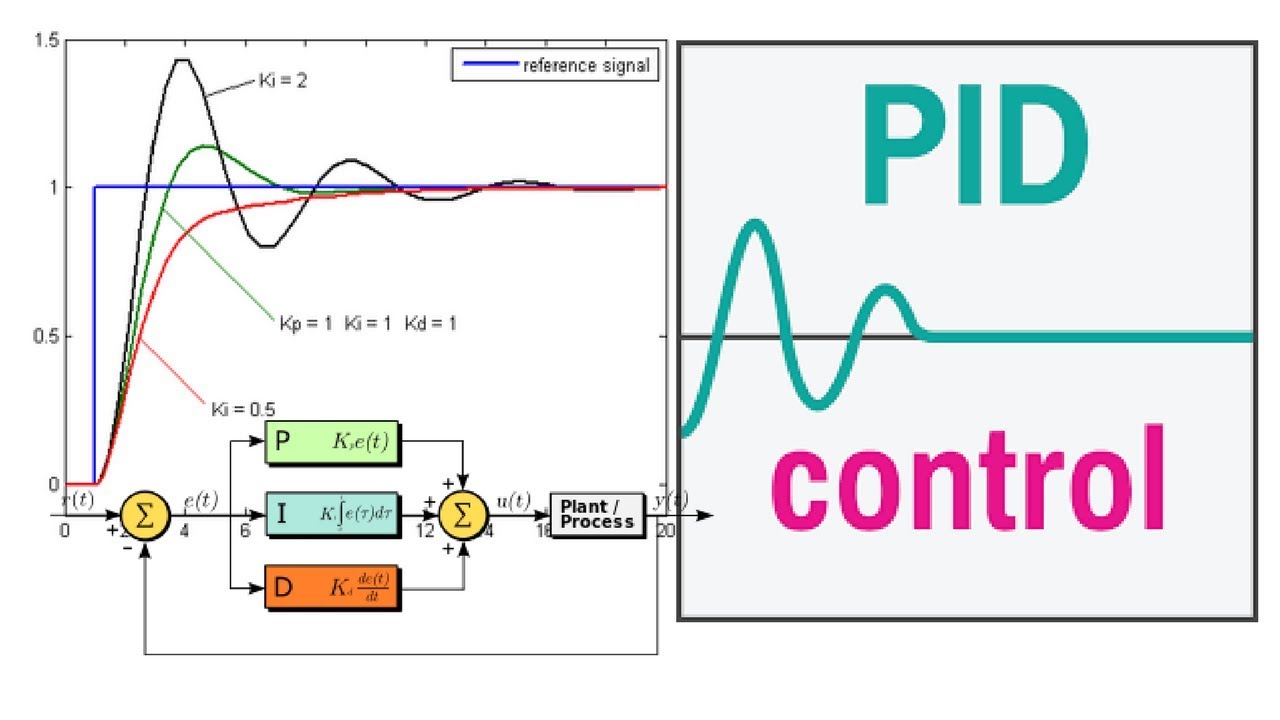

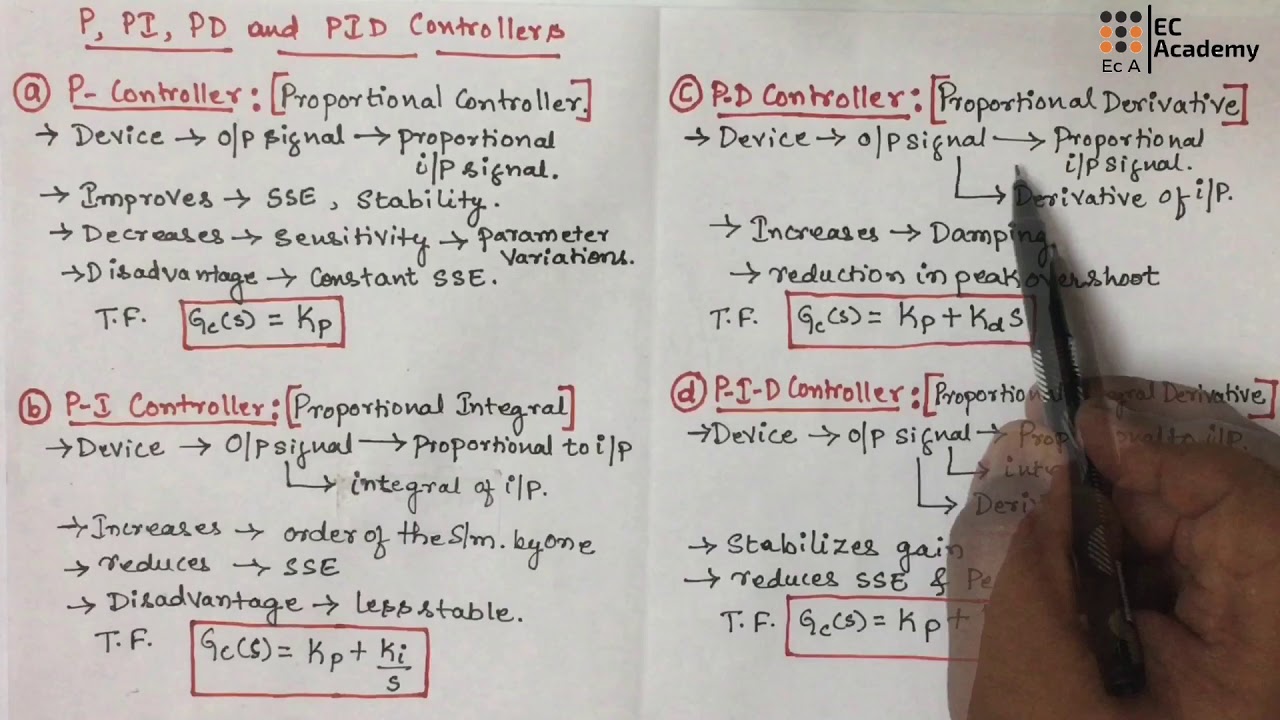

But how does this magic happen? The PI controller employs a two-pronged approach. The "Proportional" component responds to the current error, the difference between the actual value and the setpoint. A larger error leads to a stronger corrective action. The "Integral" component, on the other hand, considers the accumulated error over time. This addresses persistent errors and eliminates steady-state deviations.

The origins of PI control can be traced back to the early days of industrial automation. As mechanical systems grew more complex, the need for accurate and automated control became paramount. Early implementations were often mechanical, evolving into pneumatic and finally electronic controllers with the advent of digital technology. The development of the PI controller addressed limitations of purely proportional control, which often left a residual error.

PI control is crucial in maintaining stability in dynamic systems. Without it, processes can oscillate wildly, overshoot targets, or fail to reach desired setpoints. The biggest challenge with PI control lies in tuning the proportional and integral gains. Improper tuning can lead to instability or sluggish performance. Various tuning methods exist, each with its advantages and disadvantages.

A simple example of a PI controller is in a cruise control system. The desired speed is the setpoint. The controller measures the actual speed and calculates the error. Based on this error, it adjusts the throttle to maintain the desired speed. The integral term helps eliminate steady-state errors caused by factors like wind resistance.

Benefits of PI control include: 1) Improved accuracy by eliminating steady-state errors. 2) Enhanced stability by minimizing oscillations. 3) Robustness to disturbances, maintaining performance even in changing conditions. For instance, in a chemical reactor, PI control maintains a constant temperature despite fluctuations in ambient temperature.

Advantages and Disadvantages of PI Controllers

| Advantages | Disadvantages |

|---|---|

| Simple to implement | Can be difficult to tune optimally |

| Cost-effective | Limited effectiveness for complex systems |

| Widely applicable | Susceptible to integrator windup |

Best practices for PI control implementation: 1) Understand the system dynamics. 2) Choose appropriate tuning methods. 3) Simulate the controller performance. 4) Monitor and adjust the controller in real-time. 5) Implement anti-windup strategies.

Real-world examples: 1) Temperature control in ovens. 2) Level control in tanks. 3) Speed control in motors. 4) Pressure control in pipelines. 5) Flow control in chemical processes.

Challenges and solutions: 1) Integrator windup - Implement anti-windup techniques. 2) Noise sensitivity - Use filtering. 3) Non-linear systems - Consider adaptive control. 4) Parameter variations - Implement auto-tuning. 5) Time delays - Use predictive control strategies.

FAQs: 1) What is a PI controller? 2) How does a PI controller work? 3) How do I tune a PI controller? 4) What is integrator windup? 5) What are the applications of PI control? 6) What are the advantages of PI control? 7) What are the disadvantages of PI control? 8) How can I improve the performance of a PI controller?

Tips and Tricks: Understanding the system's dynamics is key. Proper tuning is essential for optimal performance. Simulation is a powerful tool for evaluating controller performance. Be mindful of potential issues like integrator windup and noise.

In conclusion, the PI controller, a cornerstone of control systems engineering, plays a critical role in maintaining stability, accuracy, and robustness across a vast range of applications. From regulating temperatures in our homes to controlling complex industrial processes, PI controllers are essential for achieving desired outcomes. Understanding the principles of PI control, proper tuning techniques, and best practices are crucial for leveraging its full potential. By mastering the art of PI control, engineers can optimize systems, improve efficiency, and unlock new possibilities in automation. Embracing these powerful tools empowers us to create a more controlled and predictable world. Consider exploring dedicated resources, books, and online tutorials to deepen your understanding of PI control and its transformative power in various industries.

Coloring pages printable skull when your inner goth needs an outlet

The ultimate guide to sweaty fortnite usernames

Freddie mercurys final recording a swan song of strength and vulnerability