Sink or Swim? Mastering Your Boat Bilge Pump Setup

Ever been out on the water, enjoying the sunshine and fresh air, only to feel that unsettling slosh beneath your feet? A leaky boat can quickly turn a dream day into a nightmare. But fear not, intrepid boaters! A properly installed bilge pump is your first line of defense against a watery demise. This comprehensive guide will equip you with the knowledge to tackle your own boat bilge pump installation, saving you money and giving you the peace of mind that comes with a dry hull.

Bilge pumps are essential pieces of safety equipment for any boat, from tiny fishing skiffs to massive yachts. They work tirelessly in the background, removing unwanted water that accumulates in the bilge – the lowest part of your boat's hull. This water can come from rain, waves, leaks, or even condensation. Ignoring a rising bilge can lead to instability, engine damage, and ultimately, sinking. Taking control of your bilge pump system is a critical step towards responsible boat ownership.

Historically, bilge pumps were manually operated devices, requiring constant attention and physical effort. Thankfully, modern electric bilge pumps automate this crucial task. The automatic bilge pump system consists of a pump, a float switch, and wiring connected to your boat's electrical system. The float switch activates the pump when the water level in the bilge reaches a certain point, automatically removing the water and keeping your boat afloat. This automation is a significant improvement over the manual pumps of the past, offering a far greater degree of safety and convenience.

Proper bilge pump sizing is paramount for effective water removal. A pump that's too small will struggle to keep up with incoming water, while an oversized pump can quickly drain your boat's battery. Factors influencing pump selection include boat size, typical water ingress, and hull design. Consulting with a marine expert or referencing manufacturer recommendations can help determine the ideal pump capacity for your specific vessel.

The location of your bilge pump is equally important. Ideally, it should be installed in the lowest part of the bilge, ensuring it can effectively remove all accumulated water. The pump should also be positioned to minimize interference with other boat systems and be easily accessible for maintenance and inspection. Proper wiring and hose routing are also crucial for efficient operation and preventing potential hazards. Understanding these fundamentals sets the stage for a successful bilge pump installation.

Benefits of Proper Boat Bilge Pump Installation:

1. Safety: A functioning bilge pump is your primary defense against sinking. Automatic pumps provide peace of mind, knowing that water is being removed even when you're not onboard.

2. Prevent Damage: Excess water in the bilge can damage sensitive equipment, corrode metal components, and promote the growth of mold and mildew. A reliable bilge pump prevents these costly problems.

3. Peace of Mind: Knowing your bilge pump is properly installed allows you to enjoy your time on the water without constantly worrying about potential leaks or accumulating water.

Step-by-Step Guide for Bilge Pump Installation:

1. Choose the Right Pump: Consider boat size and typical water ingress.

2. Select Location: Lowest point of the bilge, accessible for maintenance.

3. Mount the Pump: Securely attach to the hull using appropriate hardware.

4. Connect Hoses: Use marine-grade hose and clamps for a watertight seal.

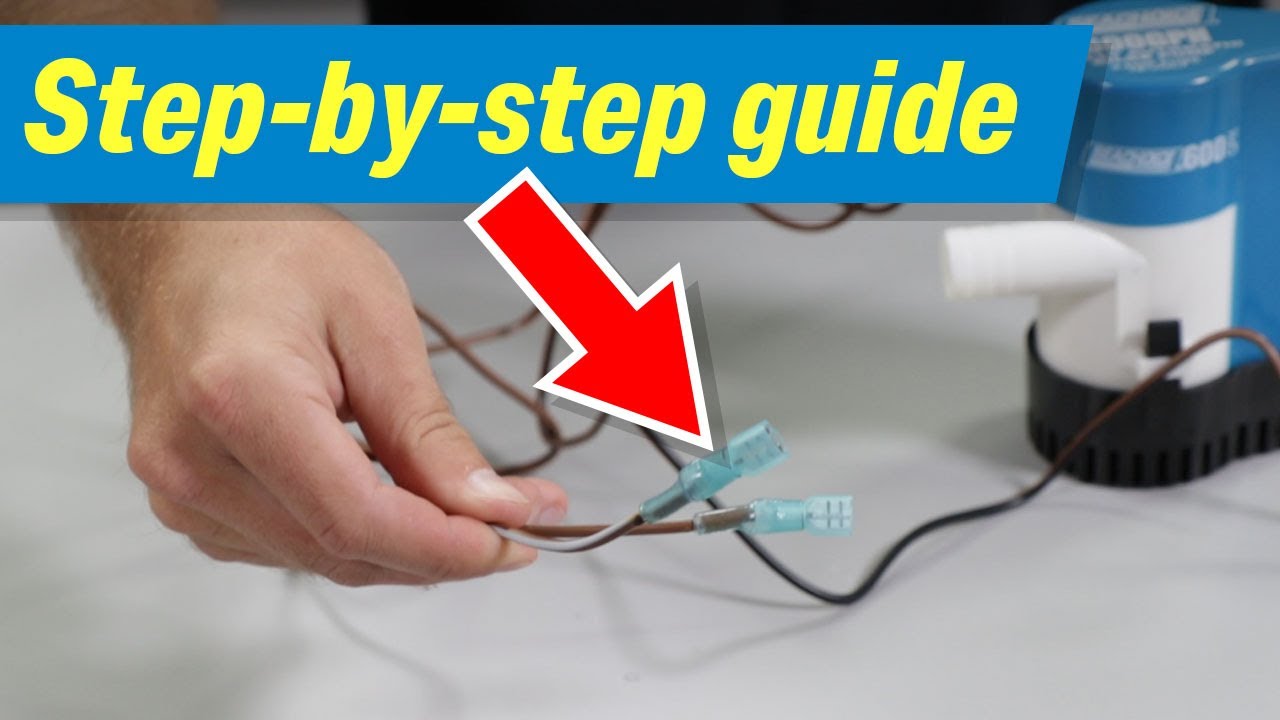

5. Wire the Pump: Connect to the boat's electrical system, following manufacturer instructions.

6. Test the System: Fill the bilge with water and ensure the pump activates automatically.

Advantages and Disadvantages of DIY Bilge Pump Installation

| Advantages | Disadvantages |

|---|---|

| Cost savings | Potential for errors |

| Increased knowledge of your boat systems | Requires time and effort |

| Satisfaction of a job well done | May void warranties if done incorrectly |

Frequently Asked Questions:

1. How often should I test my bilge pump? Monthly.

2. What type of hose should I use? Marine-grade hose.

3. Where should I mount the float switch? Near the pump, in a position to accurately detect water level.

4. What size fuse should I use? Consult your pump's manufacturer specifications.

5. How do I clean my bilge pump? Remove debris and flush with fresh water.

6. What causes a bilge pump to fail? Clogged intake, faulty float switch, or electrical problems.

7. Can I install multiple bilge pumps? Yes, for added redundancy and capacity.

8. How do I winterize my bilge pump? Remove and store in a dry location or use antifreeze in the bilge.

Tips and Tricks:

Use marine-grade wire and connectors for all electrical connections. Double-check all hose clamps for tightness. Regularly inspect the float switch for debris and ensure it moves freely. Consider installing a high-water alarm for added safety.

Installing a bilge pump is a crucial DIY project for any boat owner. By taking the time to understand the process and following the steps outlined in this guide, you can ensure the safety and longevity of your vessel. A properly functioning bilge pump offers peace of mind, protects your investment, and allows you to focus on what matters most – enjoying your time on the water. Don't delay, take control of your boat's safety and equip yourself with a reliable bilge pump system today. This simple upgrade can make a world of difference, preventing costly repairs, preserving your boat's value, and most importantly, ensuring your safety on the water. Remember, a dry bilge is a happy bilge! Now get out there and enjoy the open water with confidence, knowing your boat is prepared for whatever Mother Nature throws its way.

Myth made ink exploring greek gods tattoo designs

Level up your discord the ultimate guide to aesthetic server names

The power of unity exploring filipino poems on togetherness