Quench Your Thirst for Knowledge: Unpacking the Water Cooler Manufacturing Process

Ever stopped to wonder about the journey of your office water cooler, from factory floor to refreshing sip? It's more than just a convenient source of hydration; it's a product of a complex and fascinating manufacturing process. This article unveils the secrets behind creating these ubiquitous appliances, exploring the intricate steps involved in bringing cool, clean water to your fingertips.

The creation of a water cooler involves a series of carefully orchestrated stages, from the initial design and material selection to the final quality control checks. Each step plays a crucial role in ensuring the cooler's functionality, durability, and safety. Understanding this process offers a deeper appreciation for the engineering and innovation behind this seemingly simple device.

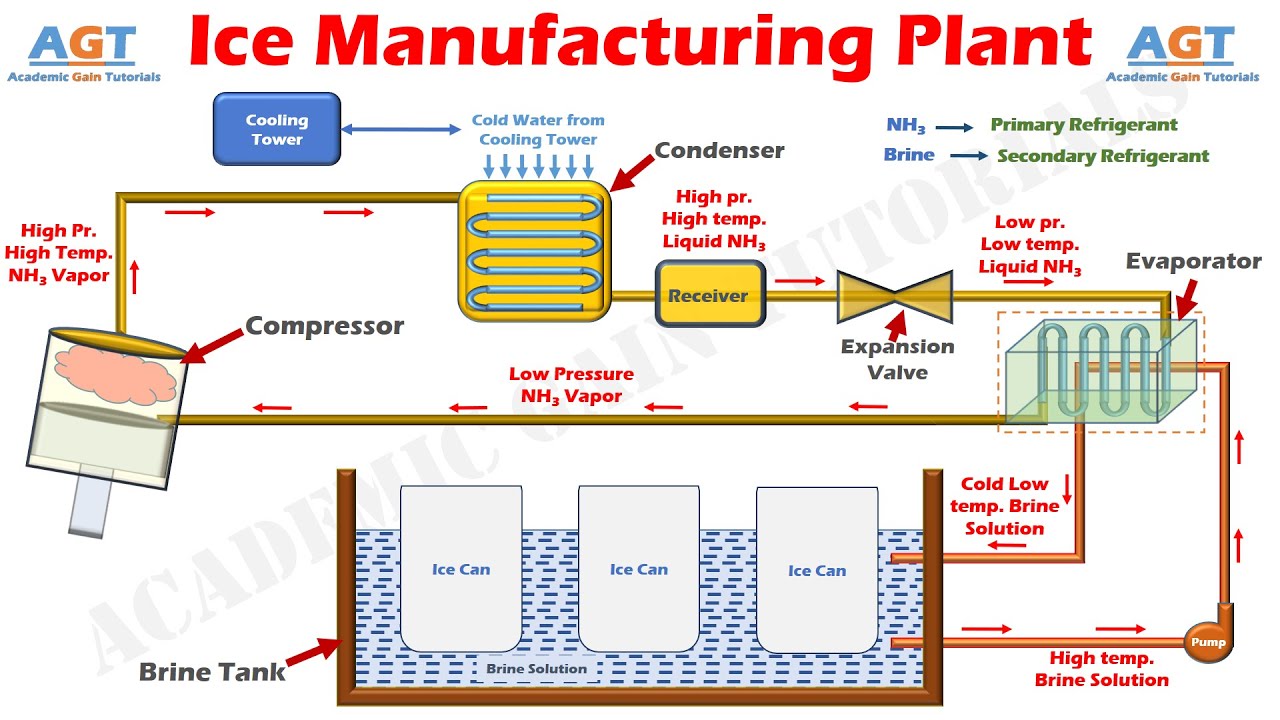

Historically, access to clean drinking water has been a constant challenge. Early water coolers were primarily focused on simple cooling mechanisms, often using large blocks of ice. The evolution of refrigeration technology revolutionized the water cooler industry, paving the way for the modern, electrically powered units we see today. This shift marked a significant advancement in providing readily available, chilled water in homes, offices, and public spaces.

The importance of a streamlined and efficient water cooler manufacturing process cannot be overstated. It impacts not only the final product's cost and quality but also environmental sustainability. Manufacturers are increasingly focused on optimizing production techniques to minimize waste, conserve resources, and reduce their carbon footprint. This commitment to eco-conscious manufacturing ensures the availability of high-quality water coolers while minimizing the impact on the planet.

One key aspect of water cooler production is material selection. Manufacturers carefully choose materials that meet stringent safety and performance standards. Common materials include food-grade plastics for the reservoirs and dispensers, stainless steel for internal components, and copper tubing for the cooling system. The selection process considers factors such as durability, resistance to corrosion, and ease of cleaning to ensure the long-term reliability of the finished product.

The water cooler manufacturing process typically involves several key steps: fabrication of components, assembly of the cooling unit, leak testing, electrical testing, and final quality control. Fabrication involves molding plastic parts, cutting and bending metal components, and preparing other necessary elements. Assembly brings these individual parts together to form the complete cooling unit. Rigorous testing ensures the cooler functions correctly and meets safety regulations.

Benefits of a well-executed manufacturing process include consistent product quality, enhanced durability, and improved energy efficiency. A well-defined process ensures that each water cooler meets the same high standards, providing reliable performance and longevity. Efficient manufacturing techniques contribute to creating coolers that consume less energy, resulting in lower operating costs and reduced environmental impact.

Advantages and Disadvantages of Different Cooling Technologies

Choosing the right cooling technology impacts efficiency and cost.

| Technology | Advantages | Disadvantages |

|---|---|---|

| Compressor Cooling | High cooling capacity, suitable for high-demand environments | Higher energy consumption, can be noisy |

| Thermoelectric Cooling | Lower energy consumption, quieter operation | Lower cooling capacity, better suited for lower demand |

Best practices include rigorous quality control at each stage, continuous improvement of manufacturing techniques, and investment in advanced technologies. Implementing these practices ensures the production of high-quality, reliable water coolers while minimizing waste and maximizing efficiency.

Challenges in water cooler manufacturing include managing material costs, ensuring consistent quality, and meeting evolving regulatory requirements. Solutions involve exploring alternative materials, implementing robust quality control systems, and staying informed about the latest industry standards.

FAQs about water cooler manufacturing often address topics such as materials used, manufacturing locations, and environmental certifications. Consumers are increasingly interested in the sustainability and ethical practices of manufacturers, driving demand for transparency and responsible production.

Tips for those interested in learning more about water cooler manufacturing include researching industry publications, attending trade shows, and contacting manufacturers directly. These resources provide valuable insights into the latest trends, technologies, and best practices in the field.

In conclusion, the water cooler manufacturing process is a complex and fascinating journey from raw materials to a finished product that provides essential hydration. Understanding this process allows us to appreciate the engineering, innovation, and commitment to quality that goes into creating these everyday appliances. As technology continues to evolve, the water cooler manufacturing process will undoubtedly continue to adapt and improve, delivering even more efficient, sustainable, and reliable hydration solutions for the future. By supporting manufacturers committed to responsible production, we can contribute to a healthier planet and ensure access to clean, refreshing water for generations to come. Investigating the specifics of a manufacturer's production practices empowers consumers to make informed decisions and choose products that align with their values. Take a moment to consider the journey of your next glass of cool water – it's a story worth exploring.

Finding peace and legacy exploring flint memorial park cemetery

Decoding cummins code spn 111 fmi 18 a comprehensive guide

Crafting the perfect roblox bio tips tricks for girls