Mastering Your Boat's Fuel Gauge: A Comprehensive Wiring Guide

Knowing how much fuel you have left is crucial for any boating trip, short or long. A malfunctioning fuel gauge can lead to unexpected and potentially dangerous situations out on the water. This guide will walk you through the essentials of boat fuel gauge wiring, ensuring you're never caught off guard.

Accurate fuel readings are not just about convenience; they are about safety. Running out of fuel far from shore can be a harrowing experience. A properly functioning fuel gauge, therefore, becomes a vital piece of safety equipment. Understanding the intricacies of connecting your boat's fuel gauge will give you the confidence to tackle this important task and ensure peace of mind on the water.

The history of fuel gauges in boats is intertwined with the evolution of internal combustion engines for marine use. Early gauges were often simple mechanical floats connected to a dial indicator. As boat engines and electrical systems became more sophisticated, so did the fuel gauges. Today, most boats use electrical sending units in the fuel tank that transmit data to an analog or digital gauge on the dashboard.

Connecting a boat fuel gauge involves understanding the components: the gauge itself, the sending unit in the fuel tank, and the wiring that connects them. A common issue is ensuring compatibility between these components. Different manufacturers use different resistance values for their sending units and gauges. Mismatched components will lead to inaccurate readings. Another common problem is corrosion in the wiring, especially in saltwater environments. This can interrupt the signal and cause the gauge to malfunction.

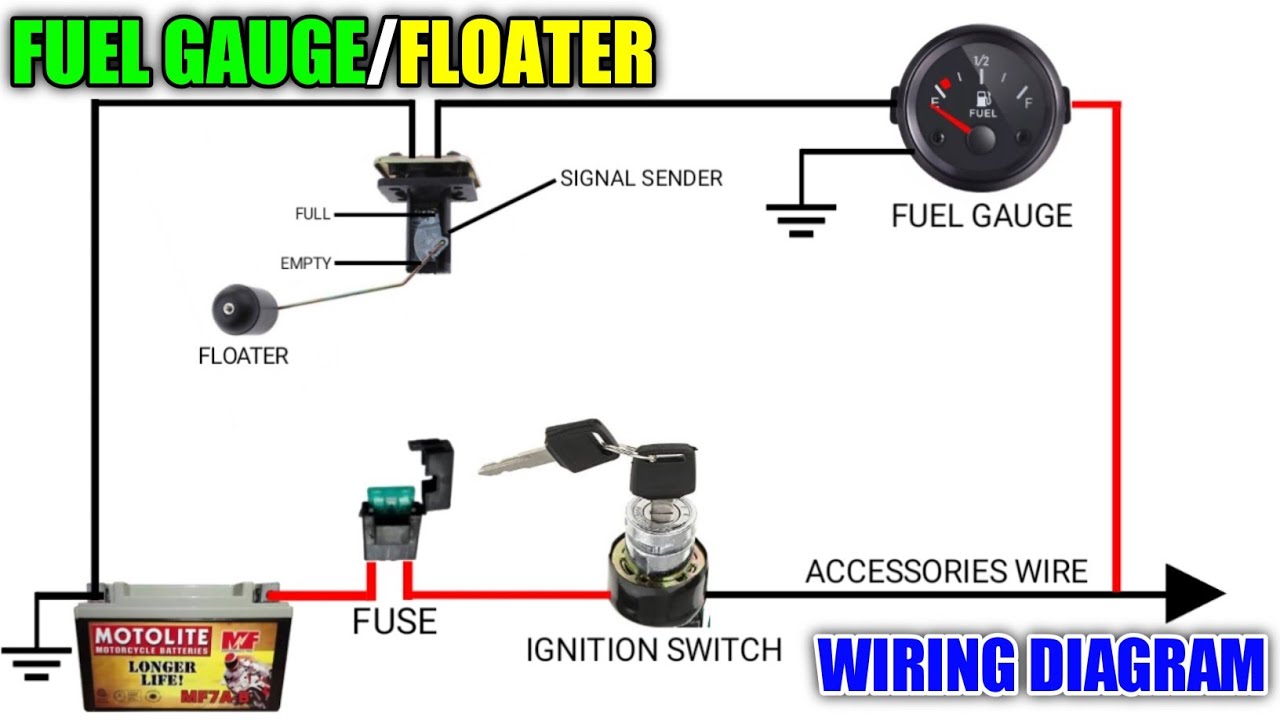

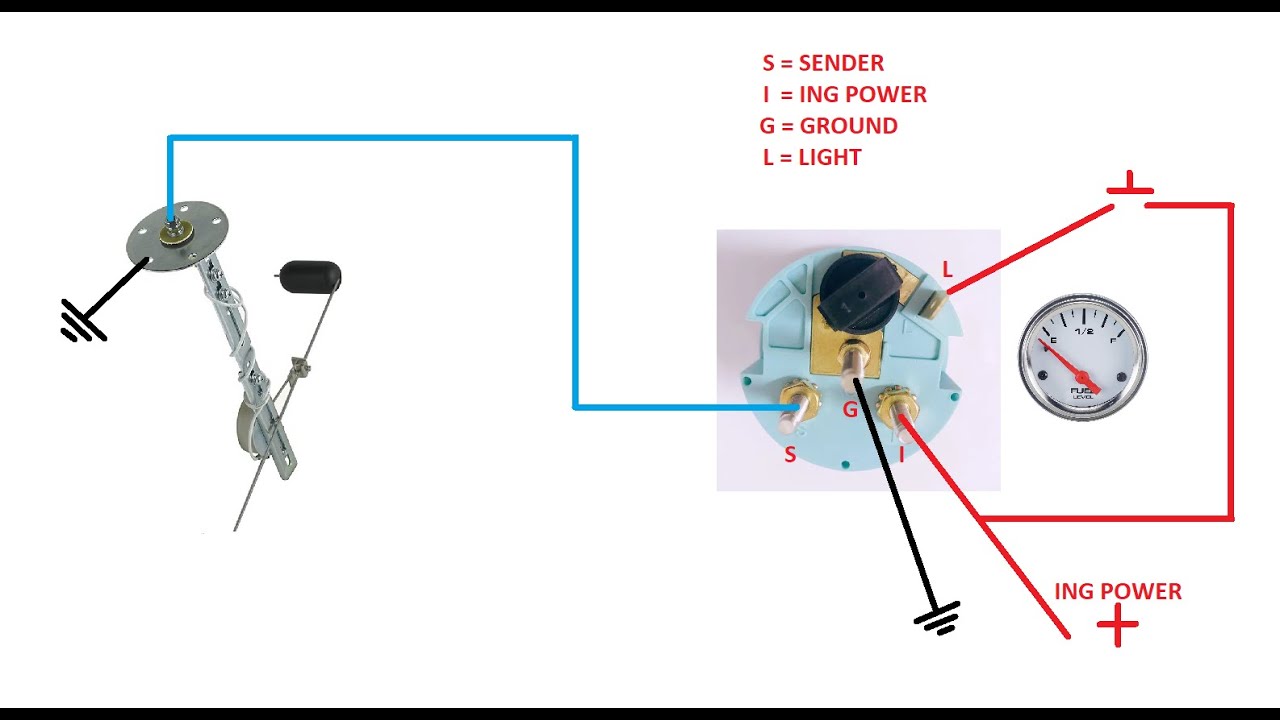

A typical boat fuel gauge system works by using a variable resistor (the sending unit) in the tank. As the fuel level changes, the resistance of the sending unit also changes. The fuel gauge measures this resistance and translates it into a fuel level reading on the dial or digital display. For instance, a sending unit might have a resistance of 0 ohms when the tank is full and 30 ohms when it's empty. The gauge is calibrated to interpret these resistance values correctly.

One benefit of correctly wiring your boat fuel gauge is accurate fuel level readings. This prevents the unpleasant surprise of running out of fuel miles from shore. Another advantage is increased safety. Knowing your fuel level allows for better trip planning and avoids potentially dangerous situations. Finally, a properly functioning fuel gauge can contribute to better engine efficiency. Running out of fuel can damage a fuel pump, leading to costly repairs.

Step-by-Step Guide to Wiring a Boat Fuel Gauge:

1. Disconnect the battery's negative terminal for safety.

2. Identify the sending unit wires in the fuel tank and the corresponding wires on the gauge.

3. Connect the sending unit's positive wire to the gauge's "S" (sender) terminal.

4. Connect the gauge's ground wire to a good ground on the boat.

5. Connect the sending unit's ground wire to the same ground point.

6. Connect the gauge's power wire to a 12V power source with a switched ignition circuit.

7. Reconnect the battery's negative terminal.

8. Test the gauge by turning on the ignition.

Advantages and Disadvantages of DIY Fuel Gauge Wiring

| Advantages | Disadvantages |

|---|---|

| Cost savings | Risk of incorrect wiring |

| Sense of accomplishment | Potential for damage to equipment |

Best Practices:

1. Use marine-grade wiring and connectors to resist corrosion.

2. Ensure compatibility between the sending unit and gauge.

3. Carefully check all connections for tightness and proper insulation.

4. Use a wiring diagram specific to your boat model.

5. Test the gauge functionality thoroughly after installation.

FAQs

1. Why is my fuel gauge not working? Check for loose connections, a faulty sending unit, or a blown fuse.

2. How do I choose the right sending unit? Match the sending unit's resistance range to the gauge's specifications.

3. Can I use automotive wiring on a boat? It's recommended to use marine-grade wiring designed for the marine environment.

4. What tools do I need? Basic hand tools, wire strippers, and a multimeter are usually sufficient.

5. How often should I check my fuel gauge? It's good practice to check your fuel gauge before every boating trip.

6. What if my gauge reading is inaccurate? Check for a faulty sending unit or incorrect wiring.

7. How do I test a fuel sending unit? Use a multimeter to measure the resistance of the sending unit at different fuel levels.

8. Can I install a digital fuel gauge? Yes, digital gauges offer improved accuracy and often additional features.

Understanding how to correctly wire a boat fuel gauge is a vital skill for any boat owner. A functioning fuel gauge not only enhances convenience but, more importantly, ensures safety on the water. By following the guidelines and best practices outlined in this comprehensive guide, you can confidently tackle this project and enjoy worry-free boating adventures. Accurate fuel readings contribute to peace of mind, allowing you to focus on the joys of being on the water. Don't underestimate the importance of this seemingly small but crucial component of your boat's systems. Investing time in understanding and maintaining your boat's fuel system will pay off in the long run, ensuring safe and enjoyable experiences for years to come.

Understanding trailer surge brakes a simple guide

Funny memes to send to your friend

Need help with your auto loan wells fargo auto loans contact number guide