Mastering Your Bilge Pump: Understanding Rule 1100 Wiring

Ever felt that sinking feeling, not from seasickness, but from a failing bilge pump? A properly functioning bilge pump is crucial for any boat owner. It's your first line of defense against unwanted water accumulation, protecting your vessel and your peace of mind. This is where understanding the Rule 1100 automatic bilge pump wiring diagram comes into play. It’s not just about connecting wires; it's about ensuring a reliable system that works when you need it most.

Imagine this: you're out on the water, enjoying a perfect day, when suddenly you notice water rising in the bilge. A quick glance confirms your worst fear: the bilge pump isn't working! This scenario is avoidable with a correct understanding of the Rule 1100 automatic bilge pump wiring schematic. A properly wired automatic bilge pump is your silent guardian, constantly monitoring water levels and activating when necessary, even when you're not onboard.

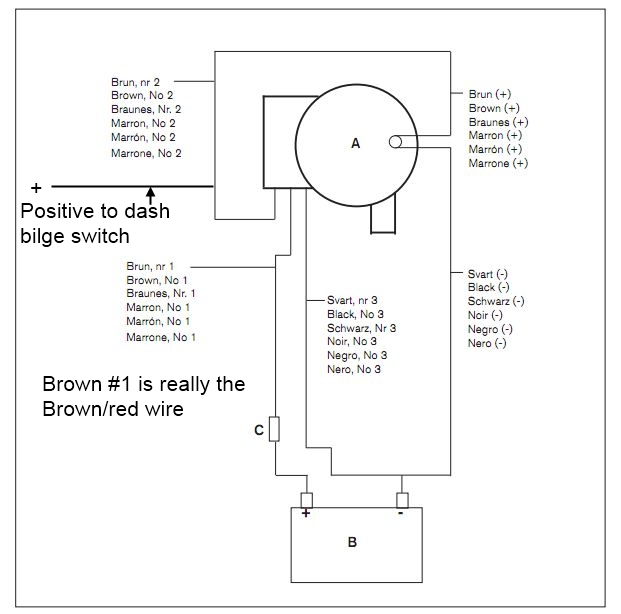

The Rule 1100 automatic bilge pump has become a standard for many boaters due to its reliability and ease of installation. But like any piece of equipment, a correct setup is key to its performance. This involves more than just connecting a few wires; it requires understanding the entire circuit, from the power source to the float switch, and ensuring all components are correctly integrated. We'll delve into the intricacies of the Rule 1100 wiring configuration, helping you confidently install or troubleshoot your system.

Now, let's talk about why this seemingly technical topic is so important. The Rule 1100 automatic bilge pump wiring setup isn't about memorizing a diagram; it's about understanding the logic behind it. This knowledge empowers you to diagnose problems, make necessary repairs, and even customize your system to fit your boat's specific needs. Whether you're a seasoned sailor or a weekend boater, mastering this aspect of boat maintenance is essential for safety and peace of mind.

We'll explore the core components of a Rule 1100 automatic bilge pump system and break down the wiring diagram step-by-step. We'll also cover common pitfalls and offer practical tips to ensure your bilge pump operates flawlessly. By the end of this guide, you'll have the confidence to tackle your bilge pump wiring project and keep your vessel safe and dry.

While tracing the precise historical origins of the Rule 1100 automatic bilge pump wiring diagram is challenging, the principles behind it have evolved alongside advancements in marine electrical systems. Early bilge pumps were often manually operated, requiring constant monitoring. The advent of automatic bilge pumps, controlled by float switches, revolutionized bilge water management. The Rule 1100, with its standardized wiring diagram, simplified installation and improved reliability, contributing to its widespread adoption.

A key issue related to Rule 1100 wiring diagrams is ensuring proper grounding to prevent corrosion and electrical faults. Another challenge is selecting the correct fuse size to protect the circuit without causing nuisance tripping. Furthermore, understanding the function of the float switch and its placement is crucial for effective automatic operation.

Advantages and Disadvantages of Automatic Bilge Pumps

| Advantages | Disadvantages |

|---|---|

| Automatic operation, requires no manual intervention | Can fail if not properly maintained or wired |

| Increased safety by preventing bilge flooding | Requires a power source, which can be drained if the pump runs excessively |

| Peace of mind, knowing the bilge is constantly monitored | Float switch can malfunction, leading to either continuous running or failure to activate |

Best Practices:

1. Use marine-grade wiring and connectors to resist corrosion.

2. Double-check all connections for tightness and proper crimping.

3. Install an inline fuse near the battery to protect the circuit.

4. Test the system regularly to ensure proper operation.

5. Consult the Rule 1100 manual for specific wiring instructions for your model.

FAQ:

1. What gauge wire should I use? Consult the pump's documentation.

2. Where should I place the float switch? In a location where it will reliably activate when water levels rise.

3. Can I connect multiple pumps to a single float switch? Yes, but ensure the wiring and fuse are appropriately sized.

4. What if my pump runs continuously? Check the float switch for proper operation.

5. How often should I test my bilge pump? At least once a month.

6. What type of fuse should I use? A marine-grade fuse with the appropriate amperage rating.

7. Where can I find a Rule 1100 wiring diagram? In the product manual or online.

8. Can I wire the pump directly to the battery? It's recommended to use a fuse and a switch.

Tips and Tricks: Label all wires clearly for easier troubleshooting. Consider adding a manual override switch for added control. Regularly inspect the float switch for debris or obstructions.

In conclusion, understanding the Rule 1100 automatic bilge pump wiring diagram is paramount for any boat owner. It's not just about keeping your boat afloat; it's about ensuring your safety and peace of mind on the water. By taking the time to understand the wiring schematic, practicing proper installation techniques, and performing regular maintenance, you can ensure your bilge pump is always ready to perform its crucial function. Don't wait for a disaster to strike; equip yourself with the knowledge and tools to keep your vessel safe and dry. Invest the time today to learn the intricacies of your Rule 1100 system. It's an investment that will pay dividends in the long run, protecting your boat and ensuring worry-free boating experiences for years to come. So, take the plunge, explore the resources available, and become proficient in the art of bilge pump maintenance. Your boat will thank you for it.

Decoding the secrets your guide to trailer vin number checks and csviewjq

Unlock your inner artist mastering cool easy animal drawings

The vietnam wall a tapestry of loss remembrance and resilience