M12 Conversion to Inches: What You Need to Know

In a world increasingly reliant on global trade and interconnected manufacturing, understanding measurement conversions is paramount. One such conversion that often arises, particularly in engineering and construction, is M12 to inches. This seemingly simple conversion holds significant implications for ensuring accuracy, compatibility, and ultimately, the success of projects.

Whether you're a seasoned engineer, a DIY enthusiast, or simply curious about the intricacies of metric and imperial measurements, this article will equip you with a comprehensive understanding of M12 conversion to inches. We'll delve into its importance, explore practical applications, and provide clear explanations to empower you with the knowledge to confidently navigate this conversion.

The designation "M12" itself holds the key to understanding this conversion. In the world of fasteners, particularly bolts, the letter "M" signifies a metric thread. The number following the "M," in this case, "12," refers to the diameter of the thread in millimeters. Therefore, an M12 bolt has a diameter of 12 millimeters.

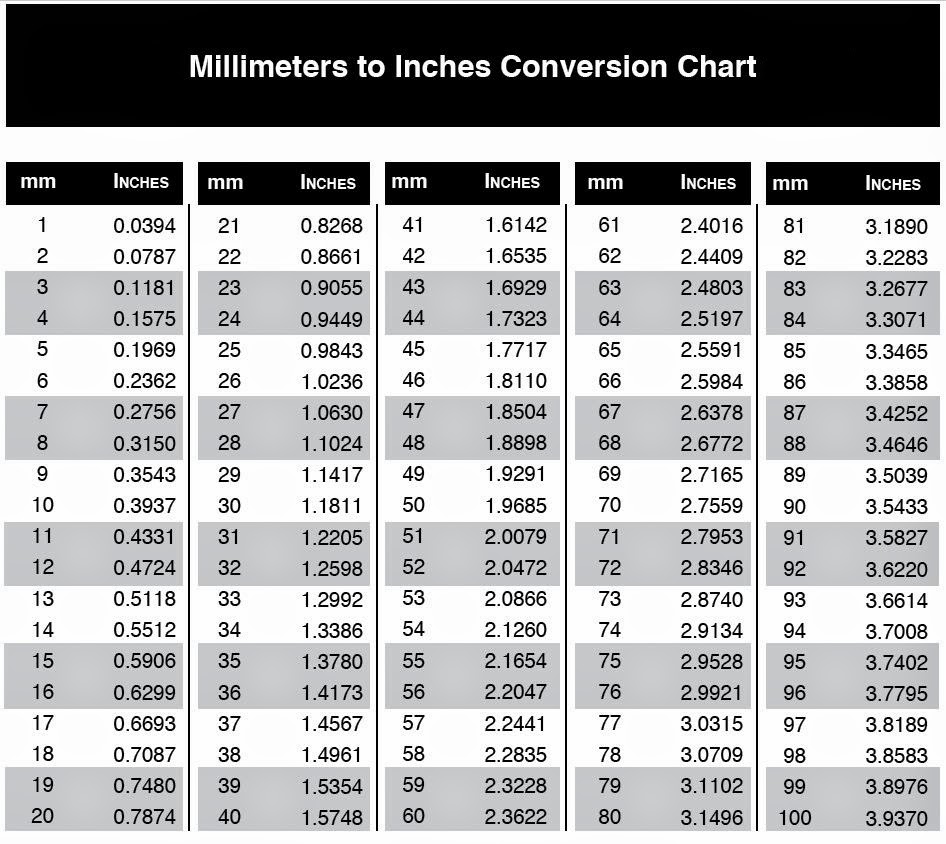

Converting this metric measurement to inches requires a simple mathematical formula. Since one inch is equal to 25.4 millimeters, to convert 12 millimeters to inches, you divide 12 by 25.4. This calculation yields approximately 0.472 inches. So, an M12 bolt has a diameter of roughly 0.472 inches.

Understanding this conversion is not merely an academic exercise; it has real-world implications. Imagine, for instance, you're working on a project that involves securing components using bolts. You have a design specification that calls for M12 bolts, but you only have access to bolts measured in inches. Without a clear understanding of the M12 to inches conversion, you risk selecting the wrong bolt size, potentially compromising the integrity and safety of your project.

Advantages and Disadvantages of M12 Conversion to Inches

| Advantages | Disadvantages |

|---|---|

| Facilitates communication and collaboration between parties using different measurement systems. | Potential for errors in conversion, especially if not performed accurately. |

| Allows for the use of components sourced from manufacturers using different measurement standards. | Can be time-consuming to perform conversions, particularly for large-scale projects. |

| Essential for maintaining consistency and accuracy in international projects. | May require specialized tools or software for precise conversions. |

While the advantages of seamless communication and compatibility are significant, it's important to be aware of the potential for errors in conversion. Mistakes in calculations or rounding off numbers can lead to inaccuracies, potentially causing delays or even safety hazards.

Therefore, it's crucial to double-check conversions, especially when dealing with critical applications. Utilizing conversion charts, online calculators, or specialized software can help minimize the risk of errors.

In conclusion, understanding the M12 conversion to inches is not just about memorizing a formula; it's about bridging the gap between different measurement systems to ensure accuracy, compatibility, and ultimately, the success of projects in our increasingly interconnected world.

By embracing this knowledge and adopting best practices for conversion, we can navigate the complexities of international standards and unlock a world of possibilities in engineering, construction, and beyond.

Finding used car treasures your guide to el pulpo auto wrecking car inventory

Discover the unique charm of downtown santa cruz shopping

Can i get checks at the bank chase your burning question answered