Level Switches: The Silent Guardians of Your Tank

Ever wonder how your coffee maker knows when to stop brewing or how a sump pump avoids overflowing? The answer often lies in a small but mighty component: the level switch. Specifically, the normally closed (NC) level switch plays a critical role in various applications, acting as a silent guardian against floods, dry runs, and other potential disasters.

A level switch, in its simplest form, is a sensor that detects the level of a liquid or other material within a tank or container. The "normally closed" designation signifies that the switch's electrical circuit is complete when the liquid level is *below* a certain point. As the level rises and reaches the switch, the circuit breaks, triggering a response such as turning off a pump or activating an alarm. Think of it as a watchful eye, constantly monitoring the liquid level and springing into action when things go awry.

These ingenious devices have a rich history, evolving from simple float-based mechanisms to sophisticated electronic sensors. Their importance spans numerous industries, from wastewater management and chemical processing to food and beverage production. Imagine the chaos without these silent sentinels: overflowing sewage systems, chemical spills, and countless ruined batches of your favorite refreshments.

A common issue with normally closed level switches, like any electromechanical device, is potential malfunction. Sticking floats, corroded contacts, or faulty wiring can disrupt the switch's operation, leading to inaccurate readings and potential system failures. Regular maintenance and inspection are therefore crucial to ensure reliable performance and prevent costly downtime.

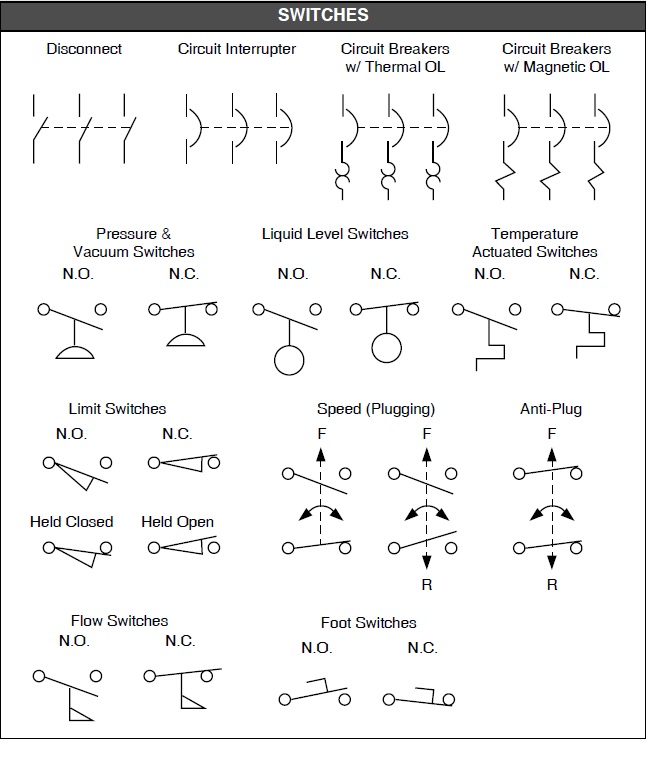

Understanding the various types of normally closed level switches is essential for selecting the right one for a specific application. Float switches, capacitance probes, and pressure sensors are just a few examples, each with its own strengths and limitations. For instance, a float switch might be ideal for a simple water tank, while a capacitance probe would be better suited for a tank containing viscous or corrosive liquids.

One of the primary benefits of a normally closed level switch configuration is its inherent fail-safe nature. In the event of a power outage or wiring failure, the circuit remains open, preventing unintended operation. This is especially important in applications where overflow could pose a significant safety hazard.

Another advantage is the simplified control logic. Since the switch is normally closed, the control system only needs to monitor for an open circuit to indicate a high-level condition. This simplifies programming and reduces the complexity of the overall system.

A third benefit is the potential for energy savings. By shutting off a pump or valve when the desired level is reached, normally closed level switches minimize unnecessary energy consumption, contributing to a more efficient and sustainable operation.

To implement a level switch, first determine the appropriate type for your application, considering the liquid's properties and the tank's characteristics. Then, carefully position the switch within the tank, ensuring proper wiring and calibration. Regularly inspect and maintain the switch to prevent malfunctions and ensure reliable performance.

Advantages and Disadvantages of Normally Closed Level Switches

| Advantages | Disadvantages |

|---|---|

| Fail-safe operation | Susceptible to false alarms if the liquid clings to the switch |

| Simplified control logic | May require more complex wiring in some applications |

| Energy efficient | Can be affected by turbulence or foam in the tank |

Five best practices: proper mounting, regular testing, correct wiring, selecting the right switch type, and understanding the liquid's properties.

Five real examples: sump pump control, overflow prevention in tanks, high-level alarm in water reservoirs, boiler water level management, and chemical processing tanks.

Five challenges and solutions: sticking floats (solution: regular cleaning), corrosion (solution: using corrosion-resistant materials), faulty wiring (solution: proper insulation and connections), inaccurate readings (solution: recalibration), and turbulence (solution: using a stilling well).

FAQs: What is a normally closed level switch? How does it work? What are the different types? How do I choose the right one? How do I install it? How do I troubleshoot it? What are the benefits? What are the common problems?

Tips and Tricks: Regularly inspect the switch, ensure proper wiring, and understand the liquid's properties.

In conclusion, the normally closed level switch is a critical component in countless applications, ensuring safe and efficient liquid level management. Its fail-safe operation, simplified control logic, and energy efficiency make it a valuable asset in diverse industries. While challenges like sticking floats and corrosion can occur, proper maintenance and selection can mitigate these risks. By understanding the intricacies of these silent guardians, we can harness their power to protect our systems, conserve resources, and maintain a safer, more efficient world. Invest in a reliable level switch today and enjoy the peace of mind that comes with knowing your liquids are under control. Learn more about level switches and find the perfect one for your needs by researching online resources and consulting with industry experts.

Streamline your pibg agm with effective program templates

Unlocking timeless elegance sherwin williams white flour exterior

Transform your home with behr exterior satin enamel paint