Fuel Gauge Mystery: Decoding Your Dashboard Dilemma

Ever glanced at your fuel gauge and been greeted by a cryptic reading, a stubborn needle refusing to budge, or a wildly fluctuating display? A malfunctioning fuel gauge can be more than just annoying; it can leave you stranded, unsure of how much fuel remains in your tank. Understanding how to diagnose this issue is essential for every driver. This guide will equip you with the knowledge to decipher the mystery behind a misbehaving fuel gauge, helping you avoid unexpected stops and costly repairs.

A functioning fuel gauge is a cornerstone of safe and reliable driving. Inaccurate readings can lead to miscalculations, potentially leaving you stranded miles from a gas station. Understanding the diagnostic process empowers you to address the issue proactively, ensuring peace of mind on the road. It's akin to knowing how to read a map – it provides a sense of control and security in your journey.

The earliest fuel gauges were simple float systems, mechanically linked to a needle on the dashboard. As fuel levels changed, the float moved, adjusting the needle accordingly. Modern vehicles often utilize electronic sensors, transmitting data to an electronic control unit which then displays the fuel level. Diagnosing fuel gauge problems involves tracing the issue through this system, from the sending unit in the tank to the gauge itself.

Common issues contributing to fuel gauge malfunctions range from faulty sending units and wiring problems to issues with the gauge cluster itself. A sending unit, submerged in the fuel tank, can become corroded, damaged, or simply wear out over time. Wiring harnesses can also become frayed or disconnected, interrupting the signal flow. Less frequently, the gauge itself may be faulty, requiring replacement.

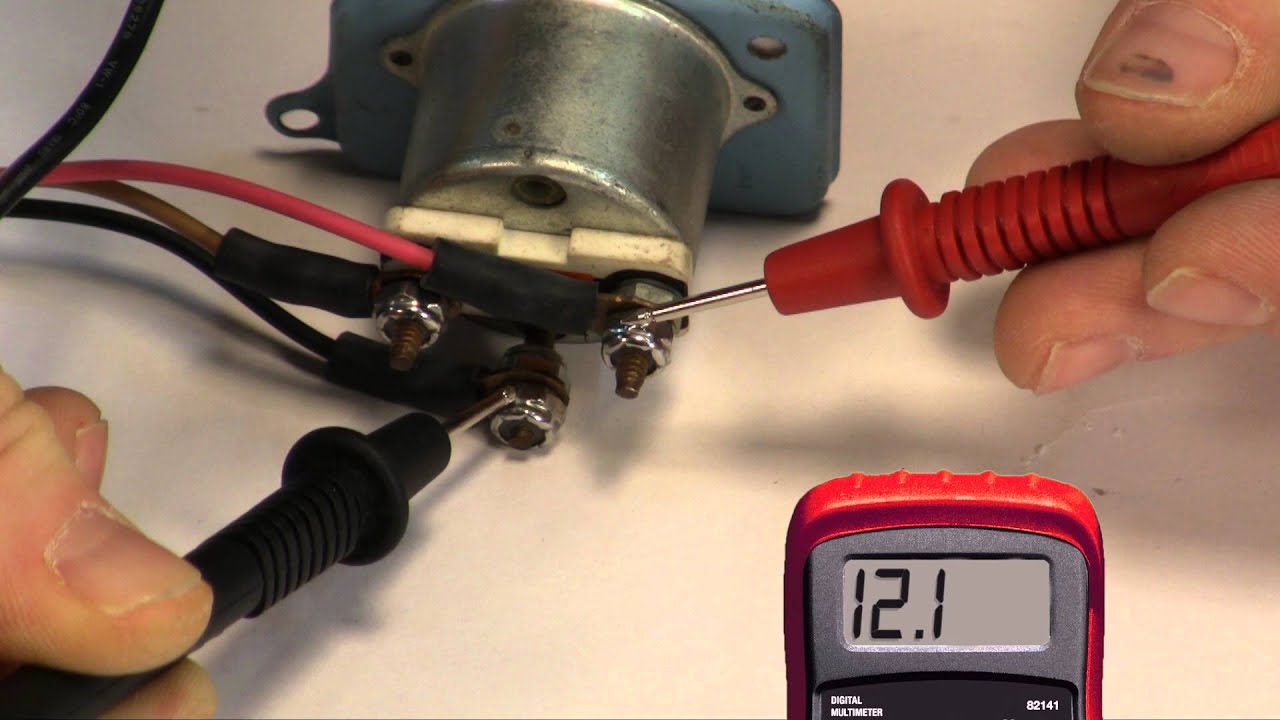

Understanding how to pinpoint the source of the problem saves both time and money. Rather than immediately replacing expensive components, a systematic diagnostic approach allows you to identify the true culprit and address it efficiently. This can involve checking fuses, inspecting wiring, and testing the sending unit’s resistance.

One benefit of knowing how to diagnose your fuel gauge is avoiding unnecessary trips to the mechanic. By understanding the basic diagnostic process, you can identify simple problems, like a blown fuse, and resolve them yourself. This saves you the cost of labor and diagnostic fees.

Another advantage is preventing the inconvenience and potential danger of running out of fuel. Accurate fuel readings are crucial for planning trips and ensuring you have enough fuel to reach your destination. Diagnosing and fixing a faulty fuel gauge prevents unexpected stops and potential hazards associated with running out of gas in unsafe locations.

A third benefit is prolonging the life of your vehicle’s fuel pump. Running the tank very low repeatedly can cause the fuel pump to overheat and wear out prematurely. A functioning fuel gauge helps you avoid this, extending the lifespan of your fuel pump.

A step-by-step guide to diagnosing a fuel gauge issue often starts with checking the fuse. Then, move on to inspecting the wiring harness for damage. Next, test the sending unit's resistance. If these steps don't reveal the problem, it could be the gauge itself.

Advantages and Disadvantages of Diagnosing Fuel Gauge Issues Yourself

| Advantages | Disadvantages |

|---|---|

| Cost Savings | Potential for Misdiagnosis |

| Convenience | Limited Access to Specialized Tools |

| Increased Car Knowledge | Risk of Further Damage if Incorrectly Handled |

Frequently Asked Questions:

1. My fuel gauge is stuck on empty. What could be the problem? A: This could be a faulty sending unit, wiring issue, or a blown fuse.

2. My fuel gauge is fluctuating erratically. What’s going on? A: This could indicate a loose connection, a failing sending unit, or a problem with the gauge itself.

3. Can I drive with a broken fuel gauge? A: It’s not recommended. You risk running out of fuel unexpectedly.

4. How much does it cost to replace a fuel sending unit? A: The cost varies depending on the make and model of your vehicle, but it can range from $100 to $500 or more.

5. How can I prevent fuel gauge problems? A: Avoid running your fuel tank very low, and ensure regular vehicle maintenance.

6. How do I test a fuel sending unit? A: You can use a multimeter to test its resistance.

7. Is it dangerous to work around the fuel tank? A: Yes, take proper safety precautions to avoid sparks and ensure adequate ventilation.

8. Where can I find more information on diagnosing car problems? A: Online forums, repair manuals, and YouTube videos can be helpful resources.

A helpful tip is to always consult your vehicle’s owner’s manual for specific instructions related to your make and model. This manual provides valuable information about your fuel system and may contain troubleshooting tips specific to your vehicle.

In conclusion, a malfunctioning fuel gauge can be a significant inconvenience, potentially leading to dangerous situations. Understanding how to diagnose the problem empowers you to address the issue proactively, saving you time, money, and preventing the hassle of unexpected breakdowns. From checking fuses and inspecting wiring to testing the sending unit, the diagnostic process outlined in this guide provides the knowledge necessary to take control of the situation. By learning to decipher the signals your fuel gauge is sending, you contribute to a safer and more enjoyable driving experience. Taking proactive steps to diagnose and address fuel gauge issues ensures both your safety and the longevity of your vehicle. Remember to always consult your vehicle’s manual and prioritize safety when working on any part of your car. Don't hesitate to seek professional help when needed, as accurate fuel readings are paramount for a safe and reliable journey.

Win yin yin md fax understanding the importance and impact

Unlocking efficiency allowing others to handle tasks

Going viral while learning the world of videos de hotspanish retos