Decoding the Enigma: Mastering Marine Fuel Sending Unit Tests

Out on the open water, there's a certain elegance to the self-sufficiency a well-maintained boat provides. It’s about understanding the intricate workings, the subtle hum of a finely tuned engine, and the confidence that comes from knowing you’re prepared for anything. One crucial aspect of this preparedness lies in understanding your fuel system, specifically how to test your marine fuel sending unit.

This seemingly small component plays an oversized role in ensuring a smooth, uninterrupted journey. A faulty sending unit can lead to inaccurate fuel gauge readings, leaving you stranded or worse, unexpectedly out of fuel miles from shore. Knowing how to diagnose and address sending unit issues is, therefore, not just a practical skill but a vital one for any responsible boat owner.

Checking a marine fuel sending unit isn't about brute force, it's about finesse, about understanding the nuances of electrical resistance and the delicate dance between the float, the sender, and the gauge. It's a process of elimination, a methodical approach that begins with understanding the system and ends with the satisfaction of a correctly functioning fuel gauge.

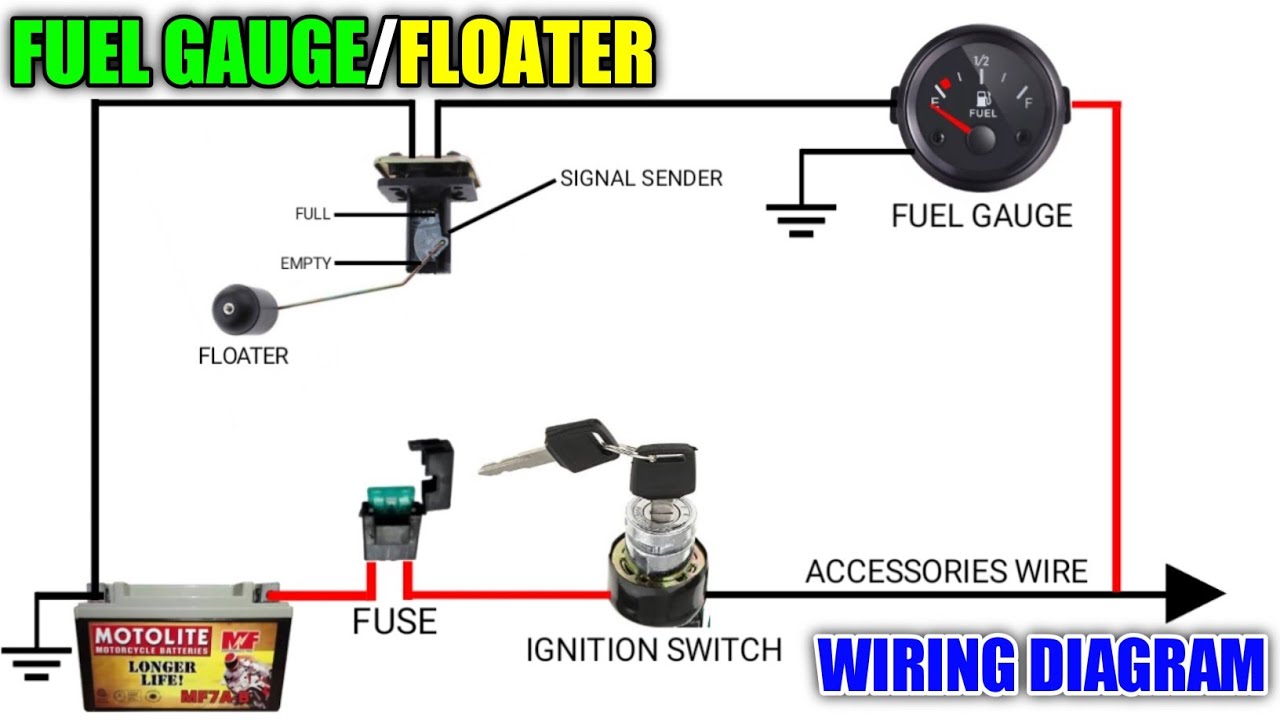

The marine fuel sending unit, in its essence, is a simple device. It consists of a float attached to a variable resistor. As the fuel level in the tank changes, so does the position of the float, altering the resistance and sending a corresponding signal to the fuel gauge. However, the simplicity of the device belies the complexity of diagnosing its potential malfunctions. Various factors can affect its accuracy, from corrosion and debris to wiring issues and gauge malfunctions.

Historically, fuel gauges were rudimentary, offering only a vague approximation of fuel levels. As marine technology advanced, so did the precision and reliability of sending units. Today's units, while more sophisticated, are still susceptible to the harsh marine environment. Understanding how to test these units allows you to identify problems early, preventing potentially catastrophic situations and ensuring the longevity of your fuel system.

One common method for testing a marine fuel sending unit involves disconnecting the wire from the sending unit and using an ohmmeter to measure the resistance. Specific resistance values correspond to different fuel levels. Comparing these readings to the manufacturer's specifications can help pinpoint issues with the sending unit itself.

Another method involves directly grounding the sending unit wire. This should cause the fuel gauge to read full. If it doesn't, the problem likely lies within the gauge or the wiring. These are just two examples, and the specific testing procedure may vary depending on the type of sending unit and fuel system.

Accurately testing your marine fuel sending unit offers several benefits. First, it ensures accurate fuel readings, preventing unexpected fuel shortages. Second, it helps identify potential problems early, minimizing costly repairs down the line. Finally, it provides peace of mind, allowing you to enjoy your time on the water without worrying about running out of fuel.

A step-by-step guide for testing a marine fuel sending unit often includes turning off the boat's power, locating the sending unit, disconnecting the wire, and using an ohmmeter to measure the resistance. Comparing these readings with the manufacturer's specifications can indicate the health of the sending unit.

Advantages and Disadvantages of Testing Your Fuel Sending Unit

| Advantages | Disadvantages |

|---|---|

| Accurate fuel readings | Requires some technical knowledge |

| Early problem detection | Can be time-consuming |

| Peace of mind | Requires specialized tools like an ohmmeter |

Best practices include using a high-quality ohmmeter, consulting the manufacturer's instructions, and ensuring proper safety precautions are taken.

Real-world examples might involve a boat owner noticing their fuel gauge reading is consistently low, leading them to test the sending unit and discover a faulty float. Another example might be a boat owner proactively testing their sending unit before a long trip, identifying a wiring issue before it becomes a problem at sea.

Challenges in testing a marine fuel sending unit can include difficulty accessing the sending unit, especially in older boats. Solutions might involve using specialized tools or seeking professional assistance.

FAQs might address questions like "How often should I test my fuel sending unit?" or "What tools do I need to test my sending unit?".

Tips and tricks might include using a multimeter with a continuity tester to check for wiring issues or cleaning the sending unit with a specialized cleaner to remove debris and corrosion.

In conclusion, mastering the art of testing your marine fuel sending unit is an essential skill for any boat owner. It empowers you to take control of your vessel’s well-being, ensuring accurate fuel readings, preventing unexpected breakdowns, and promoting the longevity of your fuel system. While the process might seem daunting at first, the peace of mind and the potential cost savings it offers are invaluable. By understanding the nuances of this seemingly small component, you contribute to the overall elegance and self-sufficiency that define the true spirit of boating. So, equip yourself with the knowledge and the tools, and embark on your voyages with the confidence that comes from knowing your fuel system is in top-notch condition. Don't just sail; sail smart.

Unlock your potential the ultimate guide to part time online remote work

Safely detaching a gas cylinder a comprehensive guide

Craving pizza in vicksburg mi 49097 your delivery guide