Conquer Bilge Pump Float Switch Wiring: The Ultimate Guide

Is your boat's bilge pump leaving you high and dry? A malfunctioning bilge pump can spell disaster for any boat owner. But fear not, because understanding the intricacies of bilge pump float switch wiring can save you from costly repairs and potential sinking situations. This guide will delve into the essentials, providing you with the knowledge to tackle this critical aspect of boat maintenance. We'll explore everything from basic wiring diagrams to troubleshooting common issues.

Imagine this: you're out on the open water, enjoying a beautiful day, when suddenly you notice water accumulating in your bilge. Your bilge pump isn’t activating! This scenario highlights the crucial role of a properly wired float switch. The float switch is the brain of your bilge pump system, triggering the pump to activate when water levels rise. A faulty connection or incorrect bilge pump float switch setup can render your entire system useless, leaving your vessel vulnerable.

The principle behind a bilge pump float switch is remarkably simple yet incredibly effective. These ingenious devices use a buoyant float to detect rising water levels. As the water rises, so does the float, eventually triggering a switch that activates the bilge pump. This automatic activation is essential for removing unwanted water, preventing it from accumulating and potentially overwhelming your boat. While the concept is simple, the actual wiring can sometimes be a source of confusion.

The history of bilge pump float switch wiring is intertwined with the evolution of bilge pumps themselves. Early bilge pumps were manually operated, requiring constant attention. The introduction of automatic float switches revolutionized bilge water management, providing a crucial safety net for boat owners. This automation significantly reduced the risk of sinking due to bilge flooding, especially in situations where immediate attention wasn't possible, such as during heavy weather or when the boat was unattended.

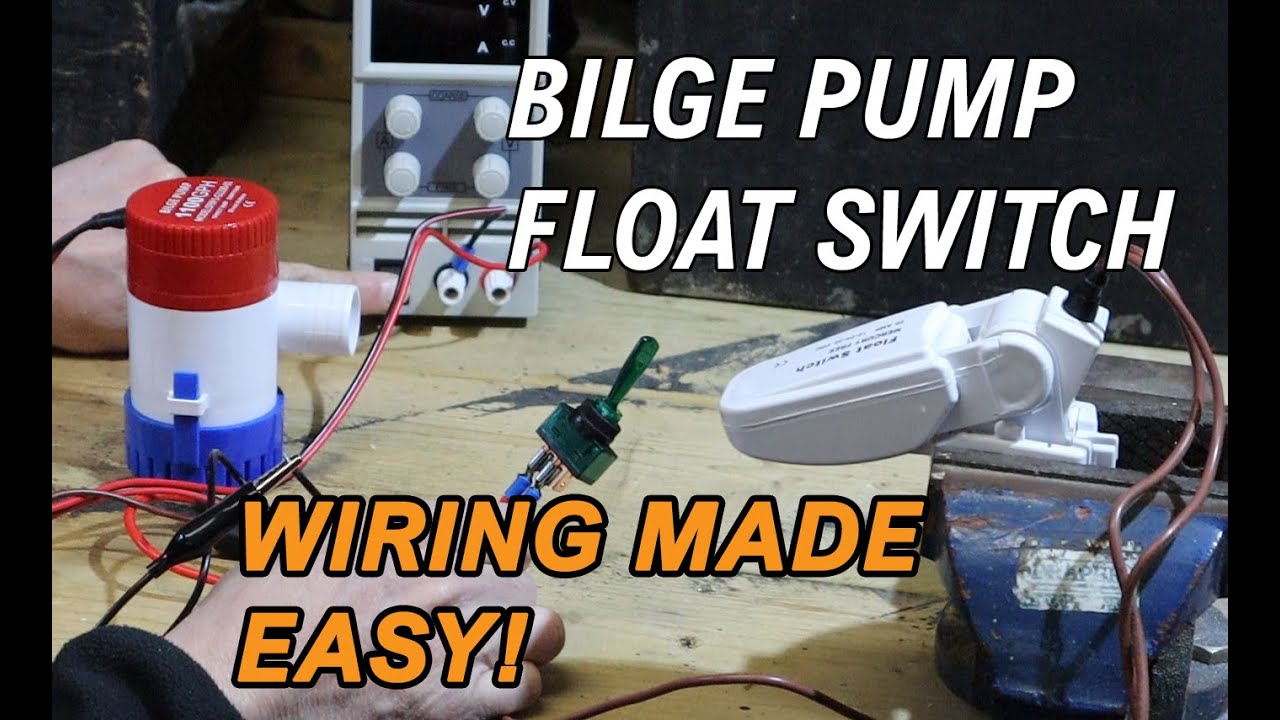

Understanding the various bilge pump float switch configurations is essential for correct installation and troubleshooting. A common setup involves wiring the float switch in series with the pump. When the float rises, the circuit is completed, allowing electricity to flow to the pump and activate it. Other configurations might involve relays or multiple float switches for added redundancy or control. Understanding these variations and selecting the right configuration for your boat is key to a reliable bilge pump system.

One of the main benefits of correct bilge pump float switch wiring is automatic bilge water removal. This prevents the accumulation of water, which can destabilize the boat and lead to sinking. Another advantage is the peace of mind it provides, knowing that your bilge pump will activate automatically, even when you’re not on board. Finally, a properly functioning bilge pump system helps protect your boat from water damage, preserving its value and extending its lifespan.

A simple bilge pump float switch wiring diagram usually involves connecting the positive wire from the power source to one terminal of the float switch, and then connecting the other terminal of the float switch to the positive wire of the bilge pump. The negative wire from both the power source and the bilge pump are connected to a common ground.

Step-by-step guide for wiring a basic bilge pump float switch:

1. Disconnect the battery power.

2. Connect the positive wire from the power source to one terminal of the float switch.

3. Connect the other terminal of the float switch to the positive wire of the bilge pump.

4. Connect the negative wires from both the power source and the bilge pump to a common ground.

5. Reconnect the battery and test the system.

Advantages and Disadvantages of Bilge Pump Float Switches

| Advantages | Disadvantages |

|---|---|

| Automatic operation | Potential for switch failure |

| Increased safety | Can be affected by debris |

| Prevents water damage | Wiring can be complex in some setups |

Best Practices:

1. Use marine-grade wiring and connectors.

2. Ensure all connections are secure and waterproof.

3. Regularly inspect the float switch for debris or damage.

4. Test the system regularly to ensure proper operation.

5. Consult your boat's manual for specific wiring instructions.

FAQ:

1. Why isn't my bilge pump turning on? (Check the float switch, wiring, and fuse.)

2. How often should I test my bilge pump? (At least once a month.)

3. What type of wire should I use? (Marine-grade tinned copper wire.)

4. Can I install multiple float switches? (Yes, for redundancy or different activation levels.)

5. How do I clean my float switch? (Remove any debris and ensure free movement.)

6. What is a normally open float switch? (A switch that closes the circuit when the float rises.)

7. What is a normally closed float switch? (A switch that opens the circuit when the float rises.)

8. How do I wire a bilge pump with two float switches? (This can be done in parallel or series, depending on the desired functionality.)

In conclusion, understanding and properly implementing bilge pump float switch wiring is crucial for every boat owner. It provides automated protection against bilge water accumulation, enhancing safety and preventing potential damage. From understanding the basic principles of float switch operation to troubleshooting common wiring issues, this guide has equipped you with the knowledge to confidently tackle your bilge pump system. By following the best practices and regularly inspecting your system, you can ensure its reliability and enjoy peace of mind on the water. Taking the time to understand your bilge pump's float switch wiring is a small investment that can yield significant returns in terms of safety and boat longevity. Don't wait until you're facing a bilge emergency – take action now and ensure your bilge pump is ready to perform when you need it most.

Disney dreamlight valley moanas boat

Unmasking the depressed emo anime boy trope

Unlocking victory your guide to fantasy baseball rankings on fantasypros